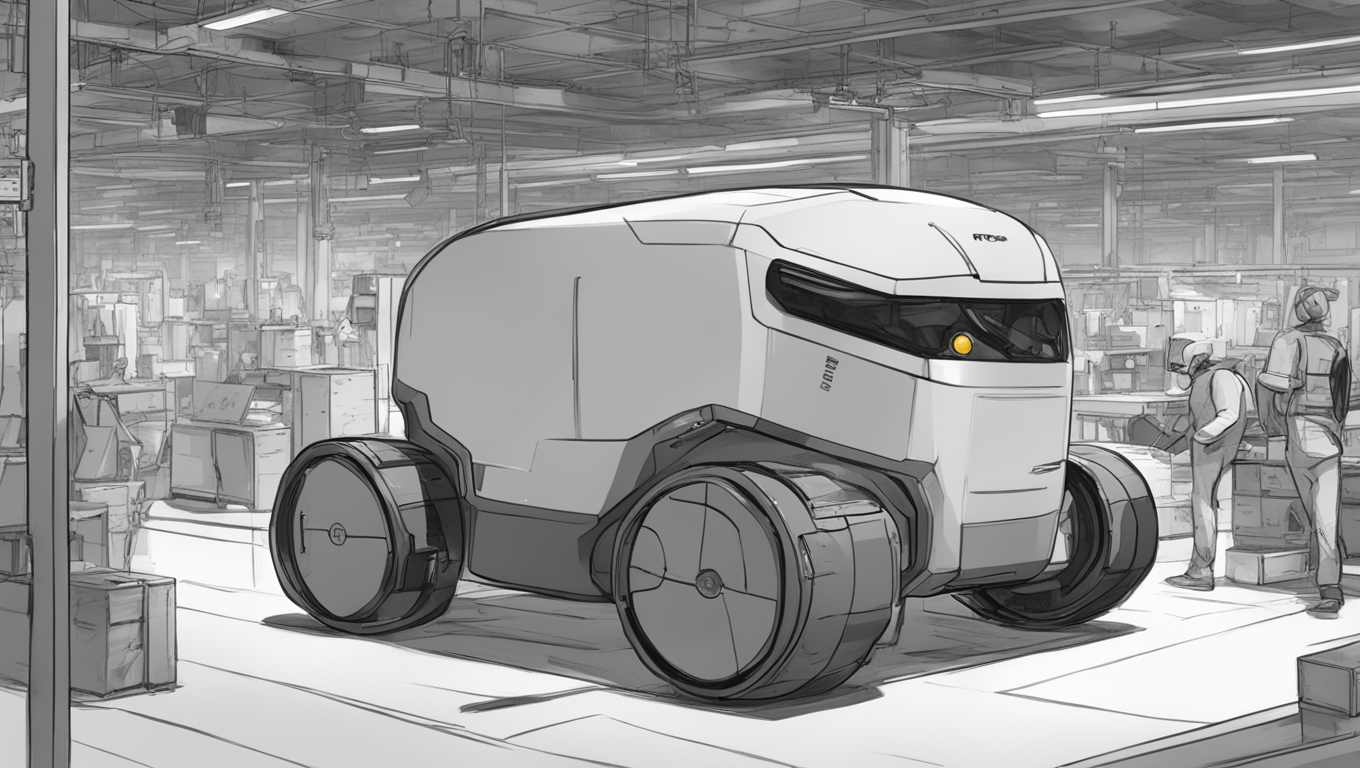

In a major leap towards the future, Piaggio, the renowned maker of Vespa scooters, has unveiled its latest creation - an autonomous factory robot named ‘kilo’. This groundbreaking robot is not just another automated machine; it is powered by artificial intelligence and can move independently on pre-set routes. Equipped with state-of-the-art technology, ‘kilo’ has the ability to carry up to an impressive 130 kilograms.

With its sights set on revolutionizing production lines, Piaggio plans to deploy ‘kilo’ on the assembly lines of its iconic motorbike brand, Moto Guzzi, in Italy. Once proven successful, the company intends to introduce this innovative robot into other factories across the globe, starting with Italy, India, Vietnam, and Indonesia.

The development of ‘kilo’ is credited to Piaggio’s U.S. robotic mobility unit, Piaggio Fast Forward (PFF). This cutting-edge machine can follow its operator, traverse up to 100 predetermined routes, or even operate autonomously. The versatility and adaptability of ‘kilo’ make it an ideal candidate for use in a wide range of industries that rely on repetitive movement of goods.

According to Greg Lynn, the CEO of PFF, “Kilo robots can move safely with and around workers in complex environments.” This underscores the robot’s ability to seamlessly integrate into existing workflows, ensuring both efficiency and safety. The long-term implications of such groundbreaking technology are incredibly promising, especially in industries that require heavy lifting or repetitive tasks.

The introduction of ‘kilo’ into the Moto Guzzi production lines will undoubtedly enhance productivity and streamline operations. The robot’s enhanced capabilities, coupled with its autonomy, will allow for reduced human intervention and increased output. By harnessing the power of artificial intelligence, Piaggio is leading the charge towards a more efficient and automated manufacturing process.

When questioned about the significance of ‘kilo’, Ray Kurzweil, renowned futurist and director of engineering at Google, hailed this development as a significant milestone in the field of robotics. He stated, “The integration of AI with robotics is an exciting frontier that will shape the future of manufacturing.”

Indeed, this integration of AI and robotics has the potential to transform the manufacturing landscape worldwide. With ‘kilo’, Piaggio is demonstrating its commitment to pushing the boundaries, not just within its own industry, but across sectors that could benefit from this groundbreaking technology.

The advent of ‘kilo’ marks a crucial step towards a fully automated and intelligent future. The combination of AI and robotics is propelling us further into a world where machines handle labor-intensive tasks, allowing humans to focus on more creative and complex endeavors.

Piaggio’s foray into autonomous factory robots is a testament to their dedication to innovation. By bringing ‘kilo’ to life, they are pioneering a new era in production and paving the way for a future where humans and machines collaborate seamlessly. This latest development from Piaggio is sure to make waves in the industry and inspire other manufacturers to follow suit.

As we embark on this exciting journey towards increased automation and intelligence, it becomes clear that the integration of AI and robotics holds enormous potential. With ‘kilo’ leading the way, we are witnessing the birth of a new era in manufacturing; an era where machines work alongside humans to create a more efficient, productive, and innovative world.

Use the share button below if you liked it.